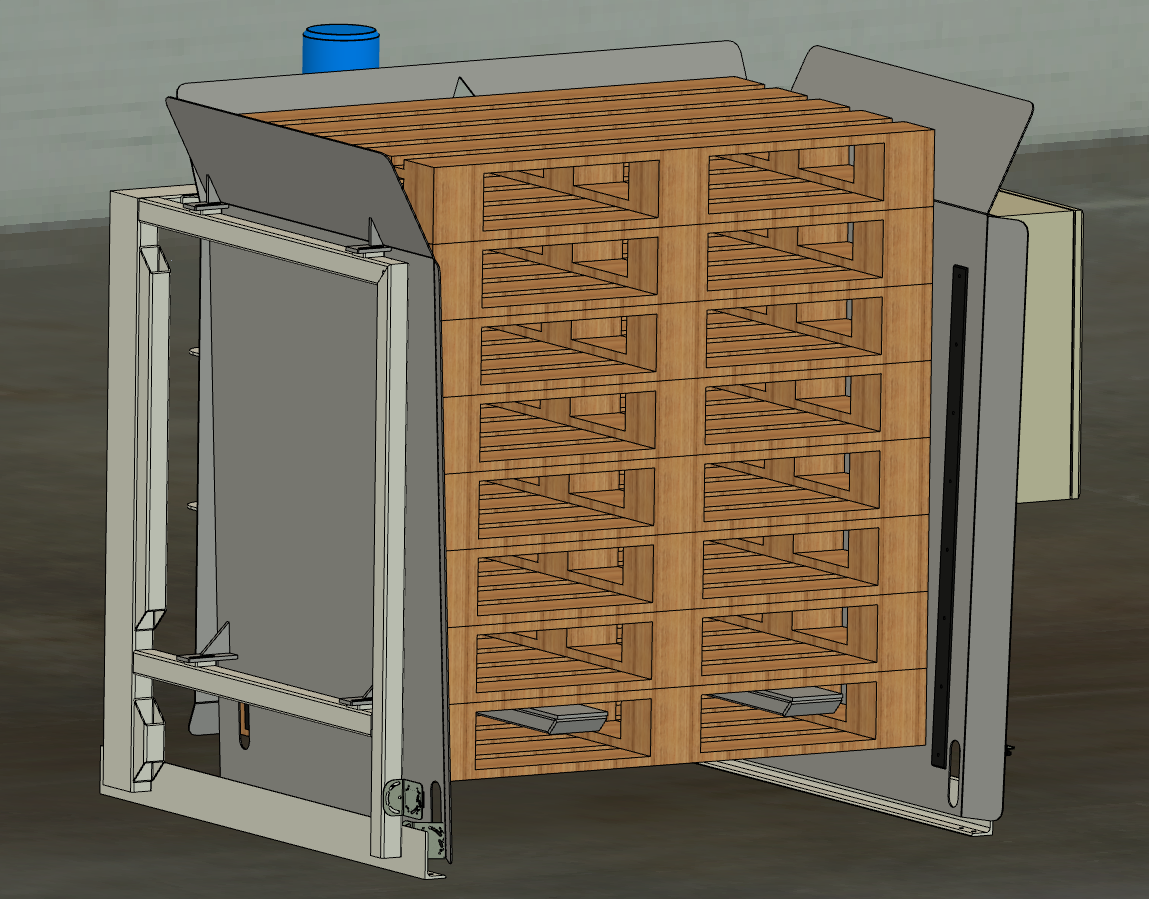

Placing pallets

A stack of up to 15 empty pallets is manually placed in the pallet exchanger.

Request and positioning

Once the pallets are loaded, the machine’s forks lower to the level of the pallet roller conveyor and place the full stack of 15 pallets on the roller conveyor.

Repositioning of the forks

The forks then retract from the stack and position themselves directly above the bottom pallet, thus in the second pallet from the bottom.

Lifting the upper pallets

The forks lift the upper 14 pallets, leaving the bottom pallet free on the roller conveyor.

Stand-by mode

The machine remains on stand-by until a request for a new pallet is received.

Discharge of the single pallet

Upon request for a pallet, the pallet is automatically discharged via the roller conveyor at the back of the pallet exchanger to, for example, a palletizer.

Start of a new cycle

As soon as the discharged pallet is in the correct position, the machine automatically starts a new cycle to destack the next pallet.