From Raw Steel to Working HerDi Machine

1. Purchasing Materials

After order confirmation, we order the required high-quality steel and cut parts.

2. Preparation and Welding

All parts are accurately cut, aligned, and professionally welded in our workshop.

3. Powder Coating

We transport the metal parts ourselves to our regular powder coater, where the parts are blasted and powder coated for a robust yet neat finish.

4. Control Cabinet Assembly

Simultaneously, we build the control cabinet entirely from scratch and thoroughly test it.

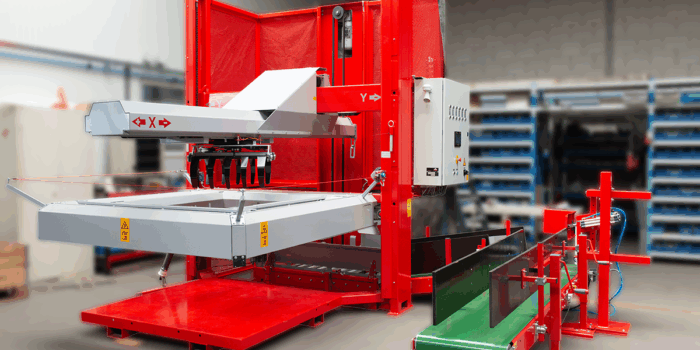

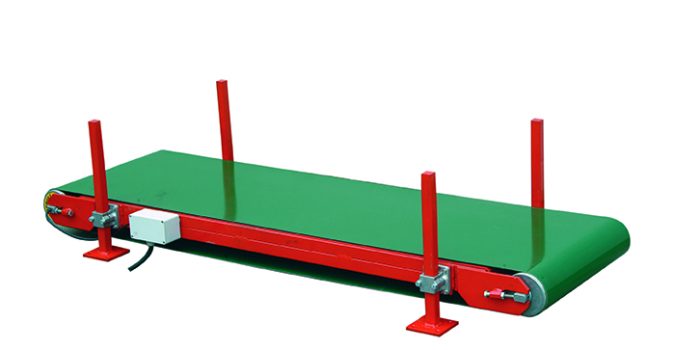

5. Assembly

We begin assembling the machine, using parts from our extensive warehouse.

6. Software Integration

Once the mechanical side is ready, we install our self-developed software.

7. Testing Phase

The complete machine is extensively tested in our workshop, both mechanically and software-wise.

8. Preparation for Transport

After a successful testing phase, we carefully prepare the machine for transport.

9. On-Site Installation

Finally, we install and test the machine on-site – our job is only done when it’s fully operational.