Herdi palletizers make excellent use of your valuable floor space.

The compact construction ensures they can be placed almost anywhere and their

design allows empty pallets to be loaded from 3 different sides.

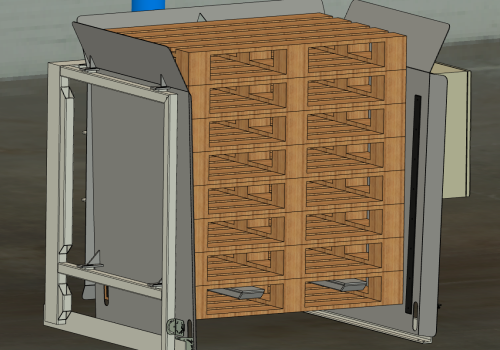

Pallet Exchanger

Herdi pallet exchangers ensure a guaranteed smooth supply of empty pallets without unplanned downtime. Thanks to the compact, modular design, our exchanger easily fits into any production line and maximizes your available space.

Flexibility:

Our pallet exchanger is suitable for all common formats (EUR-pallets 1200×800 mm and other sizes up to 800×1200 mm) and can automatically exchange both empty and loaded pallets.

- Universal fork adjustment for different pallet types

- Seamless connection with your conveyor or chain conveyor

- Compact design, minimal installation space

The control system:

The exchanger operates on a low-maintenance, electrically driven exchange unit, fully controlled via PLC and our intuitive Herdi software. Everything is fully automated and can be easily operated manually if necessary.